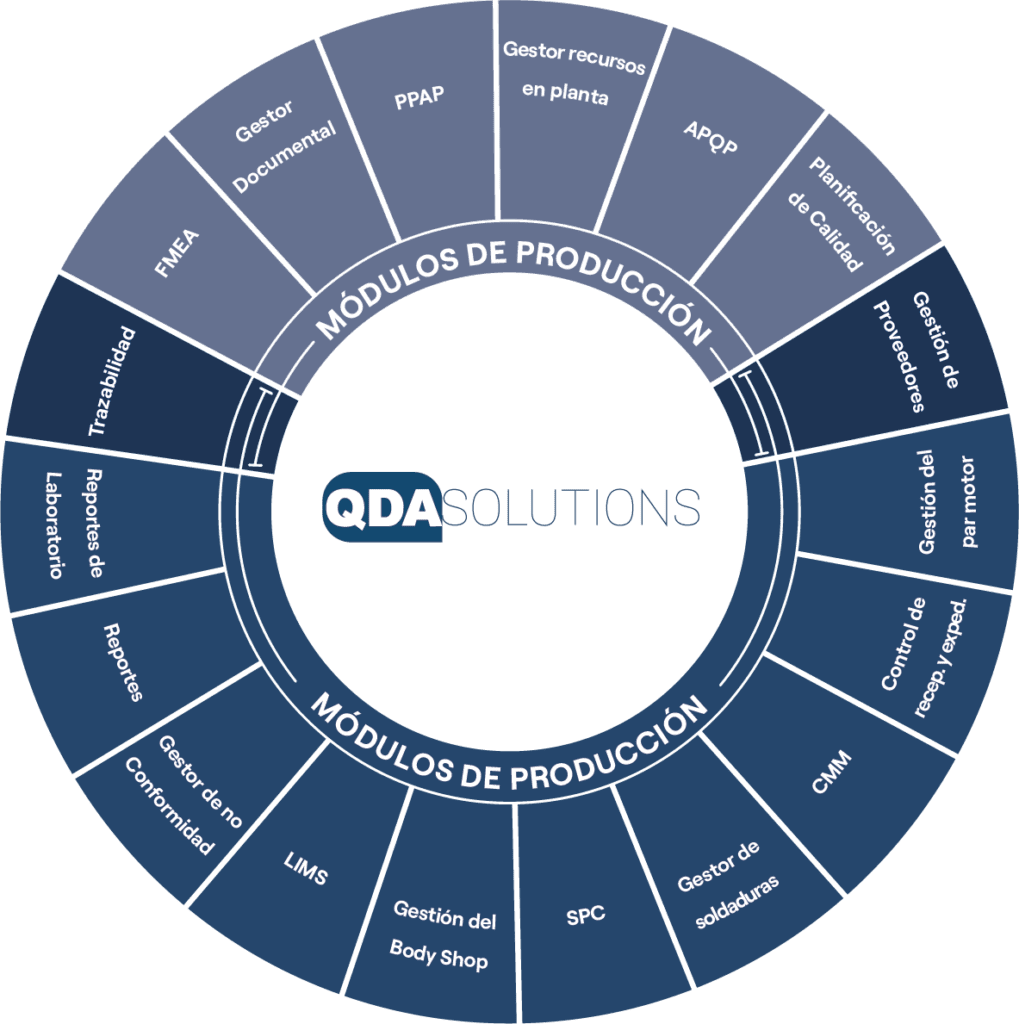

QDA is the comprehensive platform for advanced management, control and planning of quality processes, facilitating complete process traceability and comprehensive compliance with audit and certification requirements.

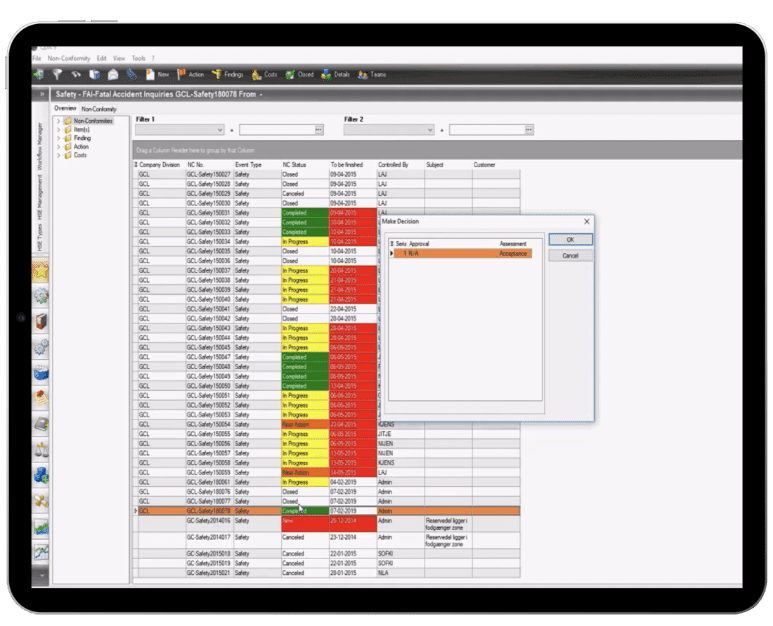

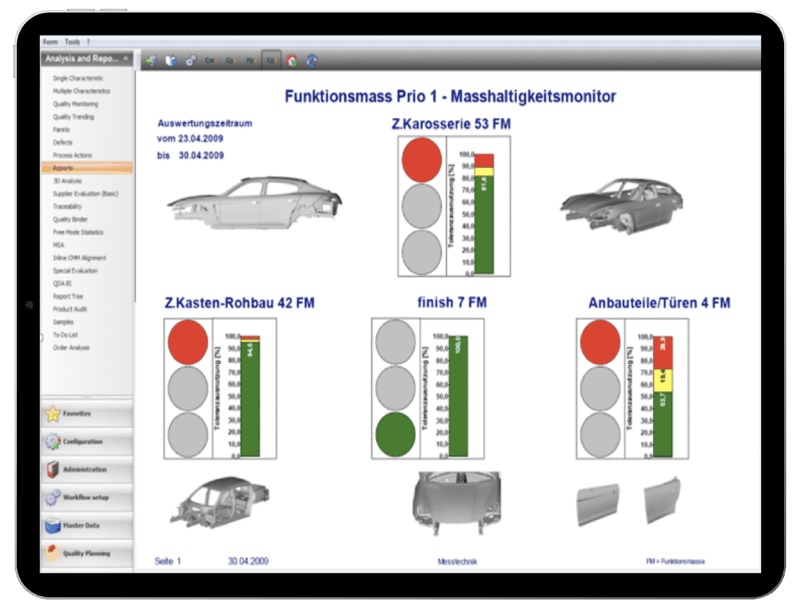

The Quality Management software focuses specifically on quality-relevant processes and data in the production environment to identify production and product defects in time and to sustainably increase production quality.