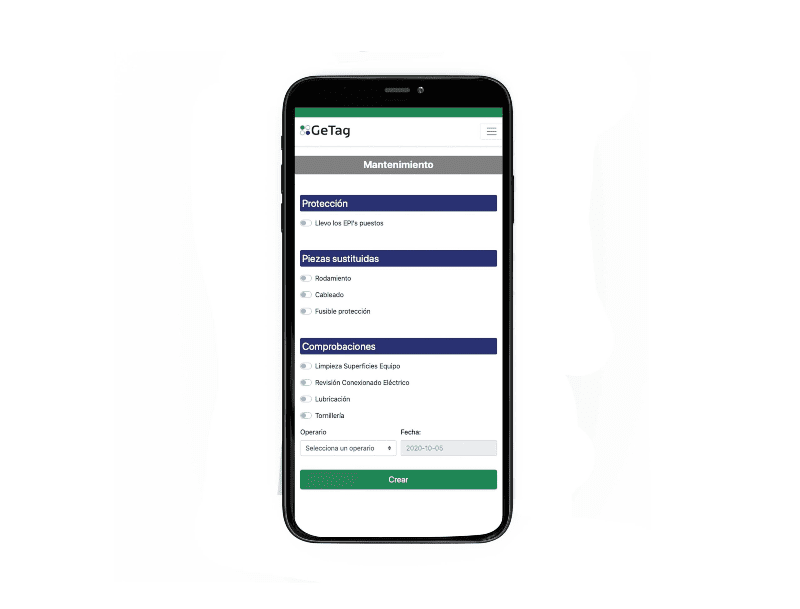

GeTag is a CMMS (Computer Aided Maintenance Management) software for the planning, control and comprehensive management of all maintenance department operations.

GeTag is designed to facilitate daily maintenance activities and decision making in real time in an efficient way, avoiding unscheduled shutdowns and breakdowns. In the same way, it is a software that allows the management of the factory’s assets and shopfloor, as well as all the elements related to the production process (machines, people, failures, spare parts, etc.).