At Geprom we are specialists in the integration and development of MES solutions for the main industrial sectors. We have the most advanced technologies in the market, from data capture and process monitoring to the management, control and integral digitalization of operations.

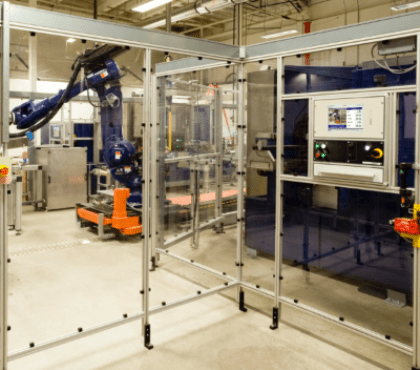

MES systems are the backbone of the digitalisation of operations, as they provide full interconnectivity at all levels of the factory: shop floor (machines, robots, automation systems, AGV’s, etc.), people, departments and higher-level systems (ERPs).