The OEE (Overall Equipment Effectiveness) is a key indicator to measure the efficiency of a machine. The plant OEE provides information on the productivity and efficiency of the plant’s production processes. In the same way, it allows to know those aspects that are not favouring productivity. Among these are identified stoppages, breakdowns, quality problems, etc.

The analysis of the OEE of the plant will allow us to know where the production processes are, in terms of efficiency and productivity, and work to improve them and achieve the best results.

To calculate OEE, we rely on three concepts: availability, performance and quality.

- Availability: it is obtained by dividing the operation time by the planned production time

Availability = time producing / planned time to produce x 100

- Efficiency: it is known as the division between what was manufactured at the time of operation, whether good or bad, between what would have been manufactured at an ideal production time.

Efficiency=actual production quantity / ideal production quantity x 100

- Quality: it is the number of good pieces in relation to the total number of pieces produced.

Quality = number of good parts / number of parts produced x 100

To perform the OEE production calculation, the three variables are applied to the following formula:

OEE = Availability x Performance x Quality

For the OEE analysis, all the concepts are expressed as a percentage (%), obtaining a result that will be between 0% and 100%, the latter being the optimal result.

Currently, many companies locate their OEE below 70%, thus having a great margin of improvement for their productivity and efficiency.

Not taking into account the OEE of the plant can generate a great loss of profitability and efficiency. On the other hand, carrying out the analysis of the OEE systems can ensure an improvement in your productivity, in your efficiency and an increase in the quality of the results.

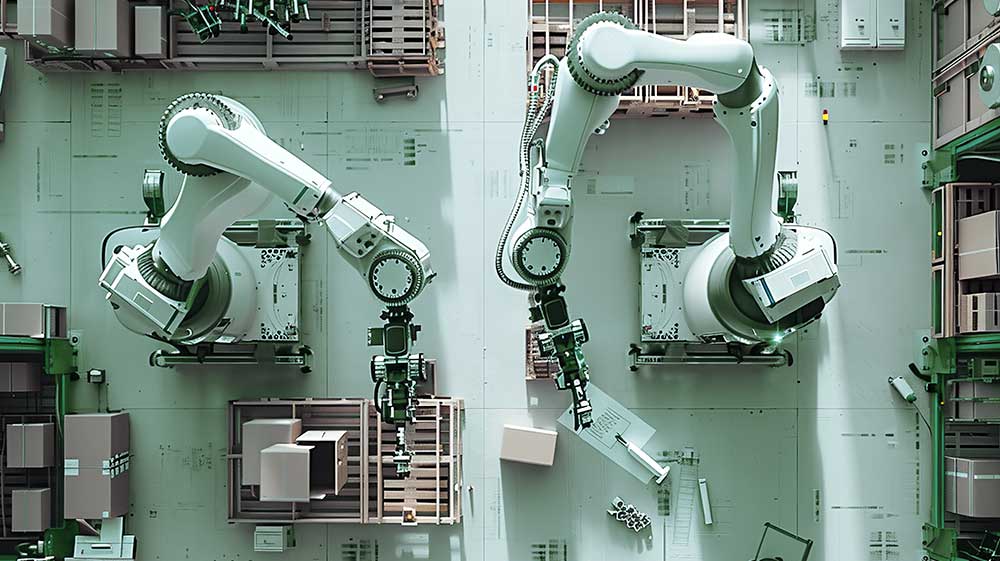

Thanks to the implementation of an MES system, a complete analysis of the OEE can be carried out, in order to know the points that are affecting productivity, both positively and negatively, and to influence them in order to obtain the best results.

In this way, we can reduce unplanned downtime. We will also be able to have a maintenance plan that helps to adjust times and reduce the occurrence of breakdowns. This will have an impact on improving availability.

We will be able to improve the speed of production by obtaining information in real time and with a good planning system that connects different departments. In this way, all operators will know the necessary information and will be able to prevent unexpected stoppages, helping to optimise plant performance.

Finally, we will reduce the “bad” products by identifying the most critical points in production and working on them to improve their performance. This will improve the overall quality of the results.

At Geprom, we are specialists with more than 25 years of experience in the Industry 4.0 sector. With the implementation of our in-plant MES systems, we have helped companies in multiple industries to significantly improve their OEE.

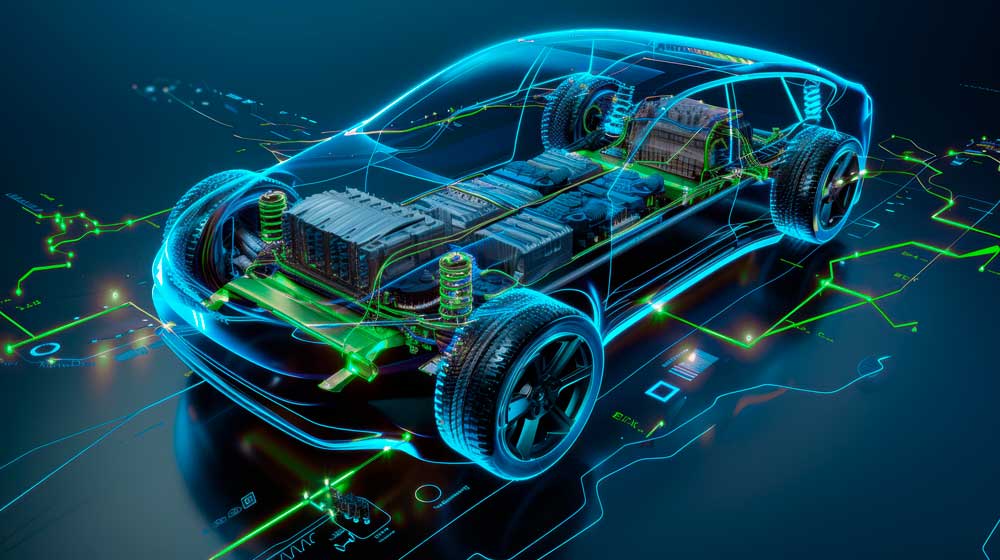

We offer the possibility of monitoring the entire production line to have real-time information and be able to have a high traceability of any type of product, in order to optimise your production process to the maximum.

In this way, we not only improve the OEE but also manage to reduce many production costs.

If you want to digitise your factory, Geprom can help you.