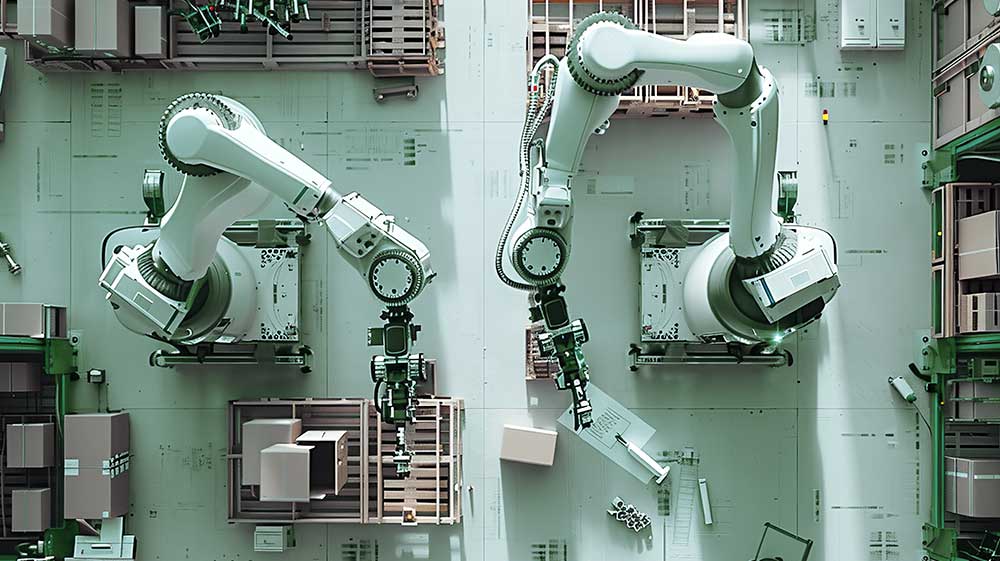

Industry 4.0 represents a breakthrough in the integration of technological innovations in production and operations using smart technologies.

Índice del contenido

What is the SCADA System?

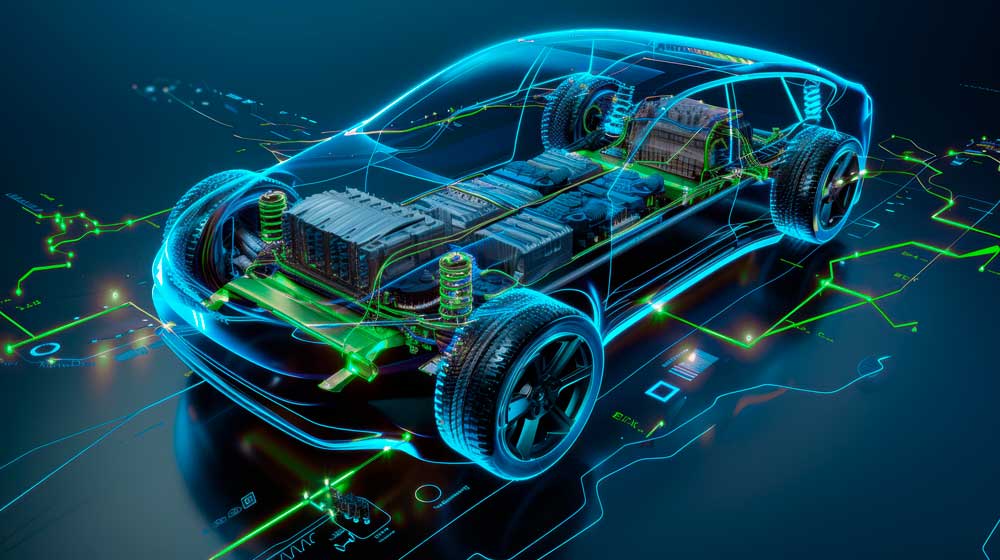

It is a field data collection system that has sensors connected to a master station in a factory, plant or other remote location, and then sends this data to a central computer and this process is carried out in real time.

SCADA (Supervisory Control and Data Acquisition) is used to monitor and control industrial equipment in virtually any industry at various stages of the development, production or manufacturing process.

SCADA system functionalities

- Control industrial processes locally or externally

- Monitor, collect and process data in real time

- Interact directly with sensors, valves, pumps, motors and more. Use of human-machine interface (HMI) software

- Recording events in a log file

SCADA system applications

SCADA system applications in industry can be very diverse. As we said, it is a multidisciplinary application suitable for the control and monitoring of processes in all types of industries. Not only does it help to visualise data, but it is especially useful thanks to its alarm system, which is able to warn of any problem detected in any area of the industrial process.

The SCADA system is applied to multiple sectors such as:

- Automotive, Railways, Aerospace

- Domotics

- Heat and Cooling

- Logistics

- Machinery, Packaging and Mechanics

- Chemical and Petrochemical

- Paper, Ceramics, Wood and Glass

- Plastic, Textile

- Water Treatment

- Research

- Food and Beverage Industry

- Power and Energy

- Agro-industry

Benefits of the SCADA system

The success of a SCADA installation depends on the use of proven and reliable technology, as well as proper and comprehensive training of all staff on the operation of the system, and these are the benefits we would find:

- Enable a large amount of data to be stored.

- Data can be displayed in different formats according to the user’s needs.

- Provide an interface to connect thousands of sensors over a wide area for various monitoring and control activities.

- Simulating real data can be achieved with the help of the operator.

- Using advanced protocols and application software, data can be monitored anywhere, not just from the local site.

- Increased safety and quality.

- Get a quick response.

- Scalable and flexible by adding additional resources.